The Multi-Agency Craft Conference (MACC), put on by the American Society of Naval Engineers, took place last week in Portsmouth, Va. The event serves as an open forum for exchanging operational and technical information on small boats and craft between government agencies and the maritime community.

Technical presentations covered a variety of different use cases, summarized by technological advancements that improve both safety and efficiency. New technology, product offerings and military information were also on display at exhibitor booths and in-water demonstrations.

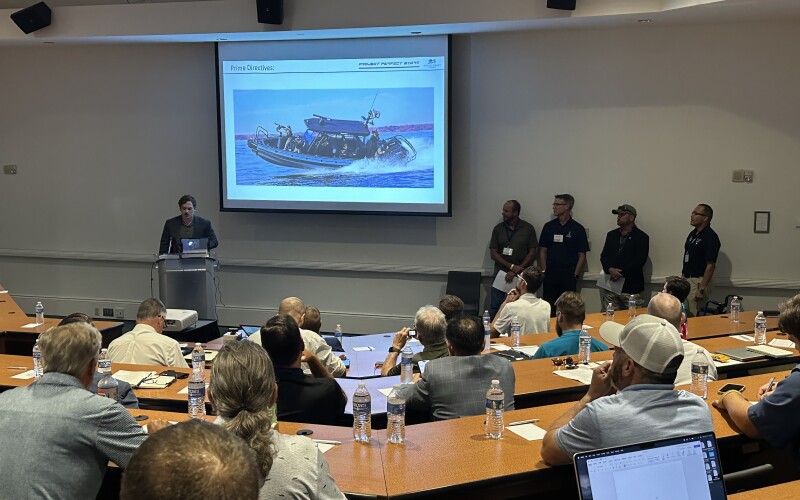

TECHNICAL PRESENTATIONS

Members of the innovation initiative Project Perfect Storm presented Ocean Craft Marine’s (OCM) 11.5-meter (37.7') Offshore Interceptor, highlighting their mission to exceed standards of safety, comfort, and performance. The team emphasized the integration of technologies aimed at minimizing the impact of high-speed maneuvers and reducing G-forces on first responders and military personnel.

The presentation underscored the collaborative effort of over 15 companies from the maritime industry, showing how competition was set aside to achieve a common goal. The cooperation serves as a model for future industry projects, demonstrating the potential of united efforts in advancing maritime capabilities. The various companies involved included Ullman Dynamics, Sharrow Marine LLC., Military Systems Group, and Hefring Marine, resulting in features like shock-mitigating seats, articulated weapon mounts, shock-absorbing deck pads, a reconfigurable deck layout, and AI-based optimal routing technology.

Todd Salus, co-founder and vice president of OCM, introduced the vessel, detailing its design and features. He highlighted the extensive working deck space, twin diver notches, and specialized shock-mitigating seats that ensure operator comfort and safety. Salas also emphasized the importance of data collection and collaboration, inviting new partners to join the project. The presentation included insights from industry experts who discussed the engineering advancements and testing processes that led to the creation of the Offshore Interceptor. Project Perfect Storm aims to significantly reduce human factors and injuries during high-speed boat operations, reflecting a commitment to improving the safety and quality of life for maritime operators.

Scott Porta’s company, Porta Products, provided the hydraulic transom brackets for the project. Porta holds 11 world and national offshore points championship titles in the APBA Super Stock Catamaran offshore racing class. “I’ve been in this stuff since I was a kid, and I absolutely love making stuff work better and go faster,” Porta noted.

He spoke to the advancements in technology being used to measure efficiency in Project Perfect Storm, making mention of his old method of hanging over a boat's transom traveling at 100 mph. “The technology that I'm hooked up with with these guys (Project Perfect Storm) is just phenomenal. And for a change, I'm looking up, I'm looking at other people that have just educated themselves tremendously.”

Keith Hubble, principal engineer at TMS Group, provided data on the Offshore Interceptor's performance, showing significant reductions in vertical, lateral, and forward accelerations due to the technologies employed. The Seakeeper ride stabilizer system, a prototype tested in various sea conditions, demonstrated control over roll and pitch, leading to a more efficient and smoother ride. The combined technologies on the modified vessel resulted in a 26% to 77% reduction in vertical accelerations compared to stock configurations.

The presentation concluded with a message about the potential impact of such advancements, suggesting that if these technologies had been available 20 years ago, many injuries and disabilities among maritime operators could have been prevented.

A separate presentation was given by Hefring Marine CEO, Karl Bjornsson, who provided an overview of his company’s AI-driven system designed to optimize safety, fuel consumption, and sustainability for maritime operations. He highlighted the system's ability to monitor and analyze real-time data, offering insights into the operational status of vessels, such as engine oil temperature and fuel consumption trends. This capability allows fleet managers to make informed decisions to enhance performance and safety, he said. Bjornsson shared that the system was initially developed for search and rescue operations in Iceland, where harsh sea conditions necessitate continuous monitoring and impact mitigation.

Bjornsson explained that the system employs a combination of center and edge computing, utilizing sensors and an IP67 embedded computer to gather data from vessels. The data is accessible through a browser-enabled console, compatible with various standard plotters. The system has been implemented in diverse maritime applications, from search and rescue missions to fuel optimization on larger vessels. He noted that the AI model continuously analyzes data to provide recommendations for optimal speed and rpm, improving fuel efficiency and extending the operational range of vessels. Through extensive data collection, amounting to over 330,000 nautical miles (and growing daily), the system has demonstrated its effectiveness in reducing impacts and enhancing overall vessel performance.

EXHIBITOR HIGHLIGHTS

On display at the show were Sharrow Marine’s futuristic-looking propellers. The company’s website notes that its propellers outperform conventional propellers in almost every category, including more command of the vessel when docking, ability to plane at 500-1,000 lower rpm, up to a 30% greater range and efficiency, less vibration and noise detection, superior handling when turning at high speeds, and up to 50% more thrust in reverse.

Sea Machines Robotics, Boston, had on display its retrofit-ready technology for autonomous navigation in commercial vessels. The Sea Machines 300 includes an onboard intelligent control hub with flexible sensor integration that pairs with a remote user rugged intuitive interface and control devices. These systems work with either newbuild or retrofit applications. The company also displayed its artificial intelligence recognition and identification system, AI-ris. Sea Machine says that AI-ris provides enhanced situational awareness, detects and tracks surface objects, classifies and geolocates multiple object types, and updates software over the air.

In April of this year, Sea Machines unveiled its latest unmanned surface vessel (USV), the Selkie 7, powered by the company’s flagship SM300 Autonomous Command and Control system. The company noted in a press release the ideal use cases — hydrographic surveys, offshore asset inspection, and water operations such as security and environmental studies.

WATER DEMOS

On both days of the conference, water demonstrations took place on the Elizabeth River, a waterway that separates Norfolk and Portsmouth, Va. RIBs comprised seven of the nine boats on display. WorkBoat’s Ben Hayden and Doug Stewart hopped onboard three of the vessels.

Among the three vessels demoed by the WorkBoat team was Ocean Craft Marine’s (OCM) 11.5-meter (37.7’) Offshore Interceptor, a rigid hull inflatable boat developed through the innovation initiative Project Perfect Storm. The Offshore Interceptor features an advanced aluminum hull, powered by triple 400-hp Mercury Marine V10 outboard motors.

The second vessel demoed was Hurricane Zodiac’s 30'x10.5' H900 multi-role boat with dual Volvo Penta D4-320A inboard engines connected to a Volvo DPI drive system and H10 propellers. Volvo’s supercharger provided more torque at lower rpm which allowed the boat to come up to plane quicker. A Volvo representative noted the company's IPS and DPI systems all contain the Volvo supercharger, which also allows for maximum thrust on joystick docking at lower rpms.

Petestep brought its 30'x9'x1.5' FUGU 29 with a 370 Mercury Mercruiser jet powered inboard. The Swedish-designed Petestep deflectors make the boat ride softer in waves, which offer the ability to travel at higher speed in rough conditions, the company’s website notes. The website also states peak acceleration is 30% lower on average.

.JPG.small.400x400.jpg)