Protect your ship with Xylem's CAPAC and Chloropac systems

In the maritime world, few challenges are as persistent and costly as hull corrosion. Xylem, a global leader in water technology, has conquered this problem for over 70 years with its CAPAC® system, a proven and reliable long-term solution for corrosion prevention.

Servicing the U.S. Navy's vessels for over 70 years, Xylem's automatically controlled cathodic protection experience dates back to the 1950's. In fact, over 60% of the U.S. Navy's vessels use Xylem's CAPAC technology. CAPAC systems have been installed on commercial vessels since the 1970's, and U.S. Coast Guard vessels since the 1990's. The Impressed Current Cathodic Protection (ICCP) system is favored over traditional sacrificial anodes for their longevity and effectiveness. Designed to last the life of the vessel, the CAPAC system provides continuous protection, reducing the need for frequent drydocking.

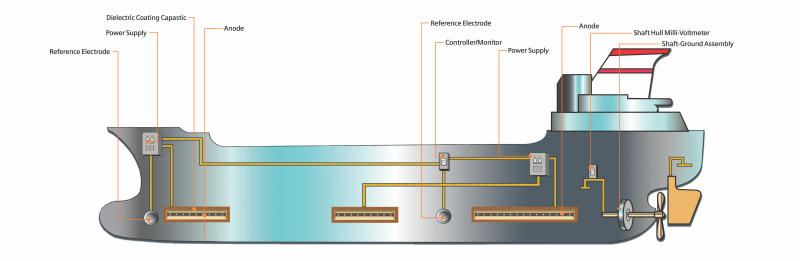

The CAPAC system includes anodes and reference electrodes strategically placed on the hull to monitor and control the electrical potential. By sending a controlled amount of DC current to prevent the electrochemical action of galvanic corrosion, your ship's hull remains in a non-corrosive state. The ICCP system has long been recognized as the superior alternative to sacrificial anode systems that require frequent replacement and have higher fuel and maintenance costs.

With thousands of world-wide installations, Xylem's CAPAC systems are widely used across various sectors within the maritime industry for preventing galvanic corrosion. They are installed on many vessels in the U.S. Naval fleet, including aircraft carriers, destroyers, and auxiliary ships. The Coast Guard also employs these systems, underlining their reliability in demanding environments. Beyond military applications, CAPAC systems are used on commercial vessels such as tugs, barges, ferries, pilot boats, service operation vessels, cruise ships, research vessels, and emergency response boats. The system's versatility allows it to be tailored for both smaller workboats and larger vessels.

Case studies and service excellence

One notable example of CAPAC system's effectiveness is its implementation on the U.S. Navy's DDG 1000 class destroyers. Images from Bath Iron Works, Bath, Maine, show the anodes and reference electrodes installed on these vessels, highlighting the system's integration into the ship's structure. This level of detail ensures the ship's hull remains protected from corrosion, significantly extending its operational life.

Xylem's commitment to service excellence distinguishes it from competitors. The company maintains a team of U.S.-based service technicians capable of providing support 24/7. This is particularly crucial for military clients who require U.S. citizenship for service personnel working on their vessels. The ability to respond quickly and effectively to service calls enhances customer satisfaction and ensures the systems operate without interruption.

Expanding reach and prospects

While CAPAC systems are primarily installed on steel-hulled vessels, Xylem also has the capability to protect aluminum hulls. Though more delicate, aluminum can benefit from ICCP systems when handled correctly. This expands the potential applications of CAPAC systems to a broader range of vessels, including those in the renewable energy sector, such as crew transfer vessels and wind support boats.

Xylem continues to innovate and refine its products to meet the evolving needs of the maritime industry. By focusing on both large-scale commercial vessels and smaller workboats, the company ensures that all market segments have access to advanced anti-corrosion and biofouling prevention technologies.

Xylem's CAPAC products offer proven success in both military and commercial applications, providing a reliable and long-lasting solution to a persistent maritime challenge. As the industry continues to prioritize efficiency and sustainability, Xylem's CAPAC systems will play a crucial role in maintaining the integrity and performance of vessels worldwide.

In the field of maritime technology, Xylem is a prominent name with its CAPAC products. Over the years, CAPAC systems have evolved technologically and remain a leader in the marine cathodic protection market, serving commercial maritime needs. The CAPAC system is also ideal for fixed platforms, floating production storage and offloading, floating liquified natural gas facilities or mobile offshore structures.

Chloropac® Marine Growth Prevention System

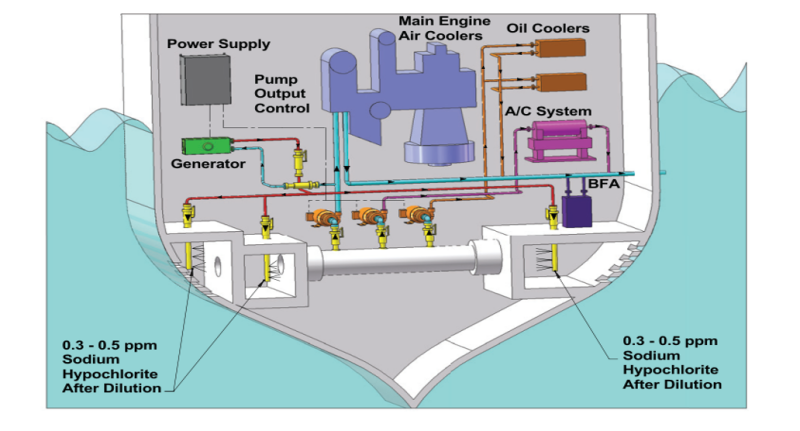

Biofouling, the accumulation of microorganisms, plants, algae, and animals on wetted surfaces, poses a significant challenge for the maritime industry. It leads to increased fuel consumption, reduced speed, and higher maintenance costs. Xylem's Chloropac system offers a proven solution to this persistent problem, ensuring vessels maintain their peak efficiencies.

The Marine Growth Prevention System, part of the Chloropac product line, addresses biofouling within the ship's seawater cooling system. By applying DC currents to seawater as it passes through specialized cells, this system generates sodium hypochlorite, which prevents the growth of algae and other organisms in a ship's piping systems, condensers, and coolers, maintaining the cooling system's efficiency and preventing blockages.

To see how this technology can benefit your fleet, visit Xylem's website and talk with a representative today.