Across the U.S., record-breaking temperatures are being predicted for much of the summer, with temperatures 15° to 25° above average. Early predictions say it could be the hottest on record in the U.S. Now, if we look at the humidity factor, life on the water for those working aboard tugs, towboats, and barges is likely to be more than just uncomfortable.

SUNSCREENS

Under those heat conditions and for many land-based jobs you wouldn’t be faulted for wearing shorts and a T-shirt, but that doesn’t work on the water. Some companies, such as Campbell Transportation, have a dress code with a requirement “for long pants, long-sleeve shirt when conducting cargo operations and mixing chemicals, and safety-toed boots where appropriate,” said Ryan Newton, Campbell Transportation’s manager of river operations, Houston.

Michael Breslin, director of safety and sustainability at American Waterways Operators (AWO), Arlington, Va., said he’s firmly in the “pants” camp because while shorts might be cooler than pants they have a lot of risks. They don’t protect your skin from direct sunlight, which can lead to sunburn and skin cancer.

Boats and barges are “like floating skillets in the summertime, causing contact-burn injuries whenever skin touches metal,” he said, whereas pants provide protection against that type of injury, as well as abrasions and lacerations from wires, ropes and tools and chemical injuries from cargo and fuel spills.

Brunt, North Reading, Mass., manufactures The Costello Pant designed for warm-weather work and made with something called a “mini ripstop fabric” that gives the pants a four-way stretch. The pants also feature a DWR (durable water-repellent) coating that deflects moisture.

With the heat that’s expected this summer, clothing that helps river crews stay cooler includes moisture-wicking and UV protection shirts, such as the Carhartt Force Sun Defender long sleeve and hooded shirt that “blocks the sun’s harmful UV rays,” said Breslin, “while drawing sweat away from the body to the garments outer surface, where it can evaporate quickly.”

On those really hot days, a cooling vest might be the apparel item of choice. “It’s probably one of the newer things in the last five years,” said Campbell Transportation’s James Werner, senior manager, safety & vetting. A cooling vest is designed to be worn under a particular work vest. It’s in contact with the skin and has pockets that hold inserts that have been pre-chilled in a freezer or cooler. The cooling vest’s heat liner is designed to keep heat out while trapping cooler air. Grainger offers insert-cooled vests in high-visibility colors with reflective colors on the front and back.

Just because it’s very hot doesn’t mean you’ll be able to get away with donning tennis shoes or any other form of lightweight footwear. Boots have always been a part of waterway apparel. Recent advances in work boot design have produced a “longer lasting, more comfortable, lighter, tougher and safer shoes for deck work,” said Breslin. A feature that’s gained in acceptance is the safety toe.

“More and more people are wearing safety- toed boots,” Werner said. That’s usually a steel-toed boot, though composite materials are also employed. “Steel or composite toes, that’s always going be a basic requirement on a towing vessel,” said Shea Milton, a pilot at American Commercial Barge Lines (ACBL) in Westlake, La.

Metatarsal (referring to the five long midfoot bones) guards and heel shank protection “add full protection to the foot,” said Campbell Transportation’s Newton, noting an advantage to boots that use composite construction. During winter months, composites don’t conduct heat through the boot.

Besides protecting your foot from impact injuries, boots must also be oil resistant, and the soles resistant to slip and shocks. Newton also likes boots that prevent the wearer’s leg when climbing a ladder from sliding forward and through the opening in the ladder.

Boots with a speed-lacing system can be quickly put on and, in case of going overboard, quickly pulled off. Lace-on boots provide ankle support, “something that pull-on boots may not provide,” said Breslin.

HEAD CASE

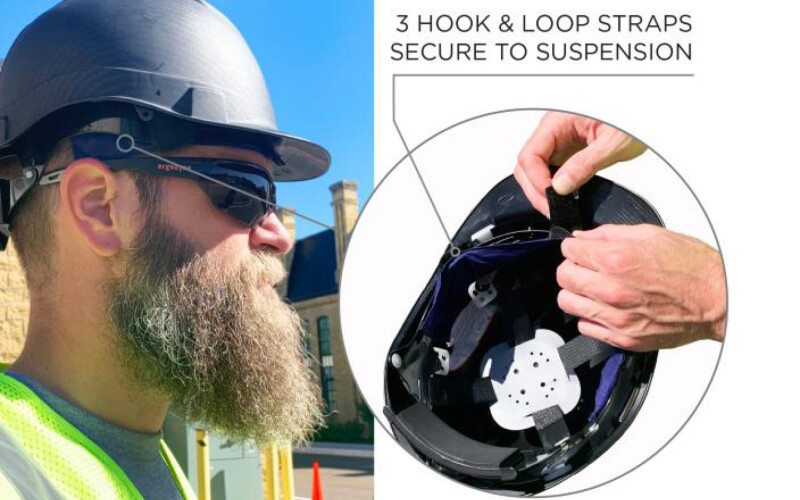

At the other end of the body, there are ways to beat back the heat encircling a river worker’s head. That includes the Chill-IT 6716 cooling liner for hard hats from Ergodyn. When soaked in water for two to five minutes, polymer crystals are activated that retain cooled water up to four hours, helping to draw heat away from the body. Re-wet to reactivate.

Cooling towels are also a weapon against the heat. After being soaked in water and put in a cooler, they are wrapped around the “neck, wrists; somewhere there’s a lot of blood flow on the skin surface, and it helps cool your core,” said Werner. A slightly different option is hard-hat sunshades and visors that attach to the hard hat and shade the river worker’s face and neck, helping him or her stay cooler.

It’s fitting that with the increasing temperatures, June is National Safety Month. One of the things Campbell Transportation highlights on its National Safety Month website is its “30 and 15 rule” for hydration and heat stress prevention. That comes into play “when the heat index — a combination of relative humidity and air temperature — is 103°F or higher,” which represents a temperature of about 94° and 50% humidity. Once that happens, the 30 and 15 rule goes into effect. The rule states that after working 30 minutes, a 15-minute break should occur to cool down and rehydrate. “That’s especially important in the Gulf [of Mexico] where humidity is a huge factor,” noted Campbell.

Gloves are another workboat protection item with a changing focus. Being phased out is the standard leather-palm work glove. ACBL has switched from that, said Milton, to impact-resistant gloves. That’s a leather glove with a rubber-like armor coating on top of the gloved hand. “Basically, it looks like armor, and the harder it’s hit, the harder that rubber instantly turns,” said Milton. “We’ve seen great success.” ACBL used to average four to five hand injuries a year, but with “the impact-resistant gloves, now we have zero hand injuries.”

UV-protected eyewear is an item that previous generations of watermen lacked. “We didn’t have those before,” said Milton. “You need that on the waterway,” both for protection from light coming directly from the sun and sunlight “that bounces off the surface of the water.” Using UV-protected eyewear should help to ensure that future generations are less likely to suffer cataracts and other eye deformities than past generations would have.

Should one be blinded by the sun or slip because of boots with inadequate soles, if you do go overboard, you’d want to be wearing a personal flotation device that is adjustable and well-fitting. The Coast Guard “requires the deck crew to wear a Type 5 PFD,” said Milton. The only exclusion “is tankermen are allowed to wear a Type 3 PFD while doing a transfer.”

Type 5 PFDs have a neck pillow that will keep the wearer’s head above water. A Type 3 PFD will not turn the wearer's face up.

Wearing the PFD gives a deckhand a good chance of being hauled back aboard, ready for another day of working the water.