Baker Marine Solutions (BMS), Covington, La., has unveiled a new concept design for the U.S. offshore wind industry.

It helps address the availability of monopiles and lack of sufficient yard space for fabrication.

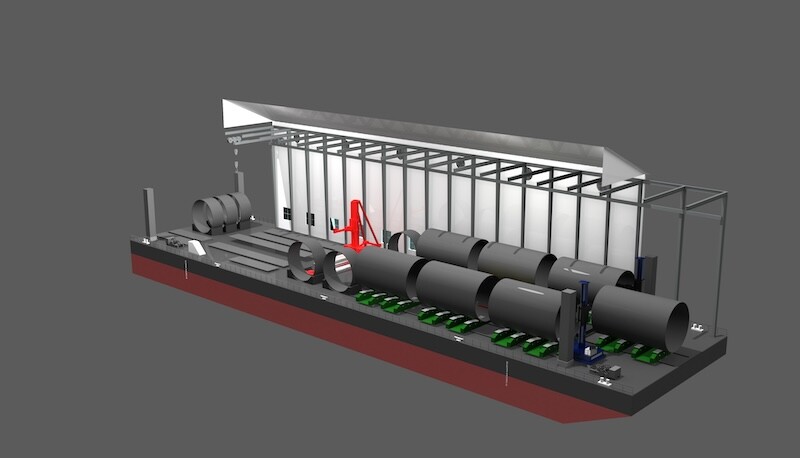

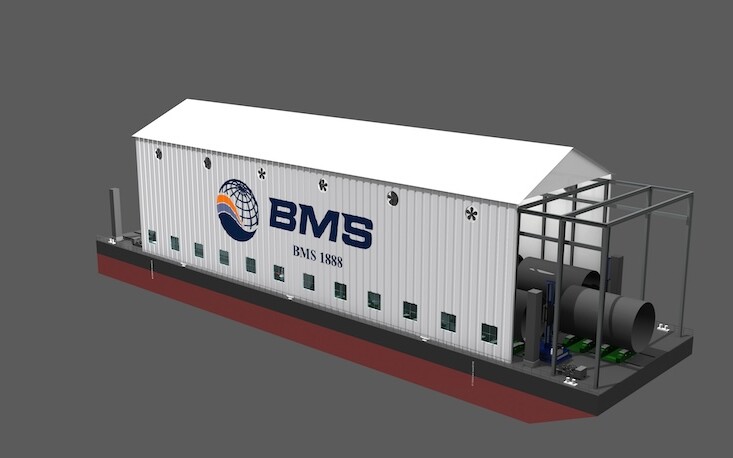

The designed is the BMS 1888 mobile pipe mill barge.

The BMS 1888 provides a mobile pipe mill facility that can be scaled to meet the requirements of any specific project. It also speeds up the initialization of the project, as the facility can be moored anywhere with appropriate water depth and height clearance.

Should available shoreside facilities not be available, the 1888 can also be mated up to additional mobile welding and coating facilities barges, creating a full-scale production line that can be rapidly mobilized to any area that can accommodate the marine footprint.

The 1888 will be fitted with two long seam weld stations, a roller arm, three welding manipulator-arms for 10' rolled plate, two stabbing stations, two stringer weld stations, two back weld stations, two welding manipulator-arms for back weld, an overhead bridge crane and gantry system, and four 60' spuds.

The 1888 will be capable of producing 10'x25' O.D. cans produced by long seam welds, and 40'x25' O.D. cans as a final product.

“The U.S. offshore wind market will require forward looking, practical solutions to complex supply chain challenges,” BMS President Jim Baker said in a statement. “The 1888 concept meets this goal.”

BMS is a provider of marine assurance, engineering and consulting services, performing DP assurance, OCIMF-OVID inspections, IMCA CMID inspections, marine warranty surveys, onboard marine representation, project management, and vessel management services.