Prospects for the offshore wind industry on the Great Lakes got a boost with an Aug. 10 ruling from the Ohio Supreme Court, allowing the Icebreaker Wind project to proceed with its plan for six turbines nine miles off Cleveland.

The Lake Erie Energy Development Corporation (LEEDC) plans for a half-dozen Vestas V126 3.45 MW offshore wind turbine generators. Energy from the wind generators would come ashore into the Cleveland Public Power grid near a decommissioned coal power plant on Lake Road, adjacent to Interstate 90.

The court ruled the Ohio Power Siting Board properly issued a permit for construction of the project, which advocates say will bring $253 million in local economic impact and create more than 500 jobs.

In writing the court’s 6-1 majority decision, Justice Jennifer Brunner said the siting board considered enough research to allow Icebreaker construction to begin, and still requires the LEEDC to continue study before the turbines can go into operation.

After 15 years in planning, the modest 20.7-megawatt Icebreaker Wind overcame objections over potential environmental impacts, including losses of bats and birds flying into the planned turbines.

Citing those wildlife concerns, two residents of Bratenahl, a lakeside Cleveland suburb, had challenged the permit. Their court effort was backed for a time by Murray Energy Corp., which paid for legal fees and expert testimony. The company had been one of the nation’s largest coal producers before going bankrupt in 2019.

The state Supreme Court held the siting board did its work effectively in considering the Icebreaker project.

“Rather than requiring Icebreaker to resolve those matters before issuing the certificate, the board determined that the conditions on its grant of the application were sufficient to protect birds and bats and to ensure that the facility represented the minimum adverse environmental impact,” according to the opinion.

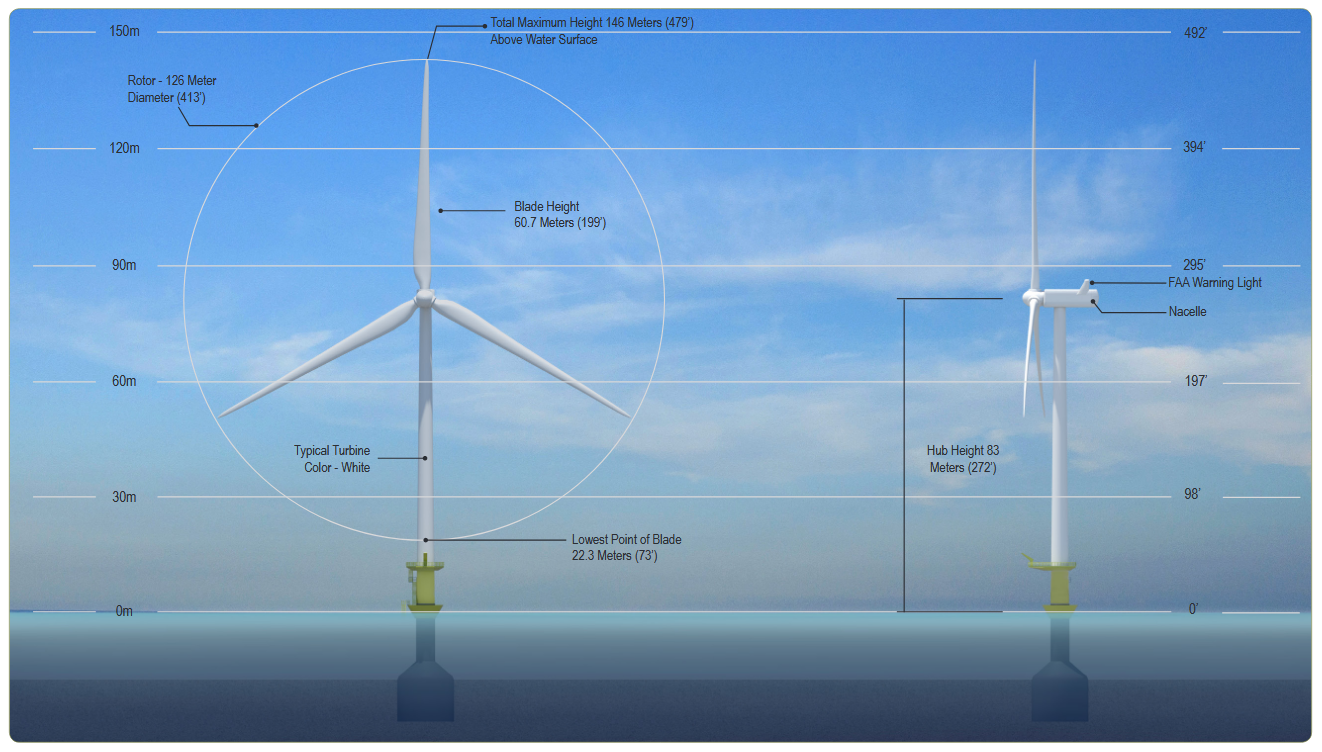

The siting board required continued environmental and wildlife studies during and after construction, and mitigation measures to reduce the risk of bird and bat losses from colliding with blades, which would extend 479 feet above the lake surface. The board had cited studies that suggested the project location eight to 10 miles offshore will reduce the risk of wildlife mortality, but issued those monitoring requirements as a condition of the permit.

LEEDC is contracted to provide one third of Icebreaker’s power output to the City of Cleveland and Cuyahoga County. With the court’s confirmation of the construction permit, LEEDC can market more power to other potential customers.

Renewable energy brings “a great opportunity to grow the wind industry locally as well as provide access to renewable energy for businesses and residents of Cleveland and the region,” said Cleveland Mayor Justin Bibb. “This project has always been a win-win for our economy and for our environment. Let’s position ourselves to be a leader, not a follower, to other states.”

Computer chip manufacturer Intel’s decision to build the world’s largest computer chip factory near Columbus, Ohio, includes a commitment to power 100 percent of its operations with renewable energy, said LEEDC board chairman and CEO Ronn Richard.

“The Court’s decision preserves the economic potential this project can unlock for the region,” said Will Friedman, president and CEO of the Cleveland-Cuyahoga County Port Authority, in a prepared statement.

Friedman noted there are estimates that $70 billion could be invested in the offshore wind business pipeline in the U.S. by 2030. By far, most is targeted to U.S. Atlantic waters close to the East Coast megapolis, but advocates see opportunity on the Great Lakes.

“Other states are nipping at our heels to attract offshore wind and its economic benefits,” said Friedman. “We don’t want to squander this opportunity and let 15 years of work slip away to other states eager to capture market share.”

The Icebreaker Wind project’s name comes from its design for surviving Lake Eire’s savage winter ice conditions. As described by the LEEDC, the “floating ice lake” that forms on the lake each winter will put two different kinds of stress on turbine towers.

“First, surface ice formed through heat transfer from the Lake Erie surface to the atmosphere can grow to be several feet thick. When driven by the winds and currents, this ice can cause steady and periodic loads on the wind-turbine tower,” the LEEDC technical documents explain.

“The second type of loading can come from ice ridges, which are formed when moving surface ice collides with stationary ice, causing the ice to pile up. The section of the ridge below the surface, called the ‘keel’, can extend downwards 20 meters (65 feet) and can create ice gouges, or scours.”

Then, water layers between the pieces of the ice keel can freeze due to heat transfer to the atmosphere, creating what the designers call a “consolidated layer” in the ridge.

Predicting those ice loads began with a look back to historical ice cover on Lake Erie, provided by the Army Corps of Engineers’ Cold Regions Research and Engineering Laboratory.

“Ice loading methodology and calculations were provided by Esa Eranti, designer of the foundations used in Finland’s offshore wind farms, where heavy icing conditions regularly exceed Lake Erie extremes,” according to LEEDC documents. Other Lake Erie experts contributed their analyses that “yielded a conservative set of loading and fatigue values that were applied to the foundation design to yield the design of the Mono Bucket structure.”

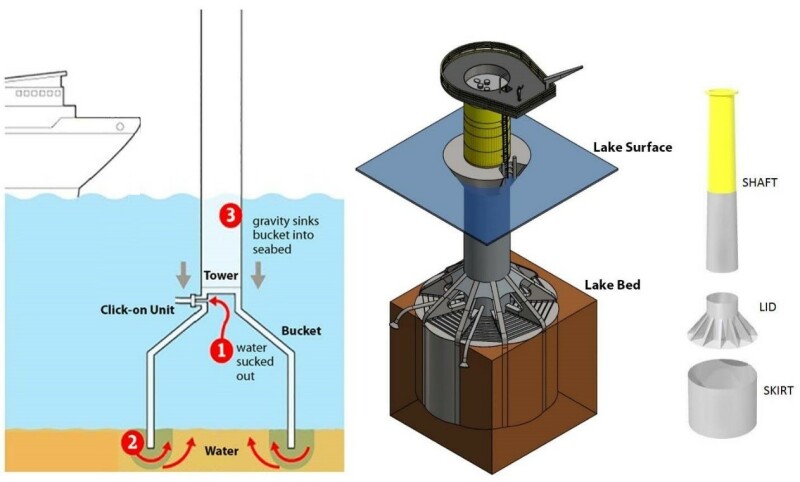

The mono bucket design combines the benefits of a gravity base, a monopile, and a suction bucket. It’s a suction installed caisson comprised of three sections: a steel bucket embedded in the lakebed, a lid/transition section between the bucket and shaft, and a shaft that resembles a standard offshore wind monopile from the mudline to the turbine interface platform above the water level.

Mono buckets have been used for decades in the offshore oil and gas industry, and deployed since 2002 in the European North Sea wind industry.

“It has proven to be a significant material innovation over earlier foundation alternatives, simplifying installation, eliminating pile driving, reducing materials requirements, and minimizing environmental impacts,” according to LEEDC documents.

Benefits include reduced installation time and costs; reduced noise during installation by eliminating the need for pile driving; and reduced environmental impacts by avoiding drilling and dredging, the agency says.