The “Swamp Shark Drive,” a new propulsion system engineered and built for extreme shallow water, has been unveiled by Louisiana boatbuilder Metal Shark in partnership with Angelle Development LLC, Breaux Bridge, La.

An entirely new system using patented technology, the Swamp Shark is designed to reliably propel vessels through dense vegetation, mud, and debris-laden water, and riverine and mud flat environments.

Inventor Clint Angelle, the CEO and owner of Angelle Development, saw his original market as fishermen and hunters who need to access the extreme shallow backwaters of Louisiana’s Atchafalaya Basin. Metal Shark executives, who market aluminum craft for military and commercial operators, saw how the system could work for those customers. Metal Shark is the exclusive OEM installer for the Swamp Shark Drive for government and military use.

When Angelle started designing in 2011, he studied the vulnerabilities of every other shallow water drive on the market and worked to overcome the challenges of operating high performance engines in these environments, Angelle said. “The result is an incredibly reliable system that performs so well that it simply must be seen to be believed,” he said.

“Swamp Shark has been on our radar since the beginning,” said Jimmy Gravois, Metal Shark’s founder and chairman. “When I learned what Clint was doing I immediately saw an opportunity to provide this new technology to our military customers, many of whom struggle with the challenges of shallow water operation.”

“Every existing propulsion system used on a riverine patrol boat is a flawed choice, because they all rely on a constant flow of clean water to operate,” said Gravois. “When the intakes clog on a military patrol boat, those troops are sitting ducks, and that sort of situation can be caused by something as simple as a plastic grocery bag floating in the water. Swamp Shark addresses this vulnerability like no other system ever invented. It is the result of an amazing application of South Louisiana knowledge and engineering that provides real, tangible benefits to military and government, commercial, and recreational boaters.”

The Swamp Shark system is based on several key components, all of completely original design: A computer numerical control (CNC)-cut, machined-steel surface drive, internal/external stabilizing hydraulics, and a specialized internal cooling system.

The drives are currently available in configurations for gas or diesel power, capable of handling up to 550 hp at the propeller shaft and 1,250 ft.-lbs. of torque, all while operating in extreme conditions. The outdrive with custom cavitation plate features hydraulic power trim and steering. A stainless steel surface-piercing propeller powers through mats of vegetation, bushes, or branches, while offering outstanding control on open water even at high speed.

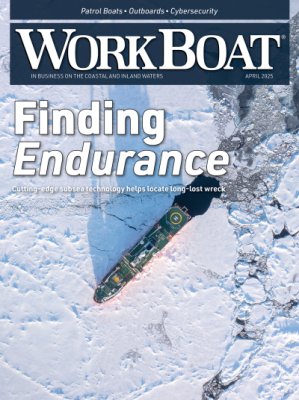

A Swamp Shark surface drive. Metal Shark photo.

A patented hydraulic-electric rebound system, which consists of actuators inside and outside of the vessel, allows the drive to smoothly and automatically adapt to conditions. When the drive impacts a solid object, such as a log, stump, or other submerged hazard, it swiftly kicks up so that the propeller will not be damaged. The system then exerts reverse pressure to instantaneously return the drive to its normal trim position as soon as the object has been cleared.

Metal Shark executives liked what they saw putting Swamp Shark-equipped boats through their paces. When they go through heavy brush and over logs and debris, “there’s a lot going on mechanically, but as the operator you’re virtually unaware of it,” says Metal Shark CEO Chris Allard. “The result is a surprisingly refined, smooth ride. The system is incredibly dynamic, always working in the background, and the results are unbelievable.”

Swamp Shark features a fully self-contained, patent-pending, onboard keel cooling system, with no appendages beneath the hull and no need for overboard raw water. This allows for smooth operation over underwater obstacles and allows a Swamp Shark-propelled vessel to traverse shallow, vegetation-clogged water or even loose mud with no cooling issues. The highly-efficient system cools engine oil, power steering and transmission fluid, and also boost-air intercoolers for turbo or supercharged engines, all with no reliance on outside water.