An obstructed check valve on a bilge pump led to the flooding and partial sinking of a towing vessel last year while moored at a shipyard near New Orleans, the National Transportation Safety Board reported Tuesday. The Joanne Marie was found partially submerged a day and a half after being moored and deactivated at a shipyard on the Harvey Canal. The vessel was unattended at the time. No injuries were reported and damage to the vessel was over $176,000. |

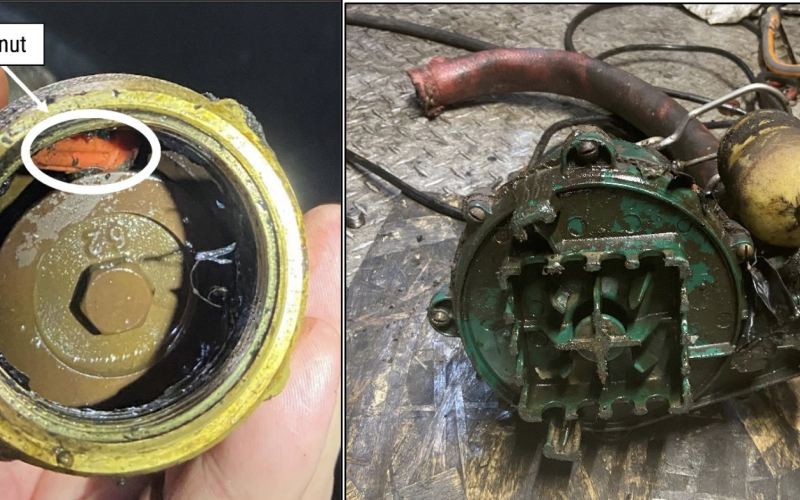

NTSB investigators found a wire nut lodged in a spring-loaded check valve on a bilge pump discharge line for the propeller shaft seal cofferdam, an enclosed box with an open top that collected dripping seal water when the towboat was underway.

The wire nut obstructed the valve and left it stuck partially open. Investigators also found the discharge line’s overboard shutoff valve before the through-hull pipe had been left open, as the operating company’s towing safety management system did not direct the crew to close it during deactivation.

In addition, the through-hull pipe for the vessel’s cofferdam overboard discharge was located close to the water line, which allowed water to enter the discharge line.

Investigators determined that with the spring-loaded check valve stuck partially open and the vessel’s overboard shutoff valve open, water was able to enter the through-hull pipe opening, causing the cofferdam to overflow and water to flood the engine room.

The NTSB also found the operating company’s inadequate procedures for securing unattended vessels contributed to the sinking. Following the sinking, the operating company modified their checklist for vessels entering deactivation to include closing the overboard shutoff valve when a vessel was not connected to shore power.

“It is good marine practice for owners and operators of towing vessels to assess risks and develop tasks in their towing safety management system (TSMS) for vessels that are unattended or in layup status,” the investigators’ report said.

“TSMS task lists for such vessels should address factors in the configuration of the vessel that could lead to a casualty. To reduce the potential for flooding, operators should consider closing through-hull fitting valves (such as skin valves or seacocks) and tightening packing glands for propulsion shaft seals, or other machinery, as needed."

"Additionally, conducting periodic rounds of vessel spaces and installing high-water bilge alarms and fire detection systems that remotely alert responsible personnel facilitates the early detection and mitigation of potential safety risks, such as flooding or fire.”

The NTSB’s Marine Investigation Report 24-07 is available online.

.png.small.400x400.png)