Isover's ULTIMATE stone wool is not just an insulation product but a comprehensive solution that enhances operational efficiencies, reduces environmental impact, and offers significant cost savings, setting a new standard in the marine insulation industry. This innovation exemplifies the future of sustainable and efficient shipbuilding.

What is Stone Wool?

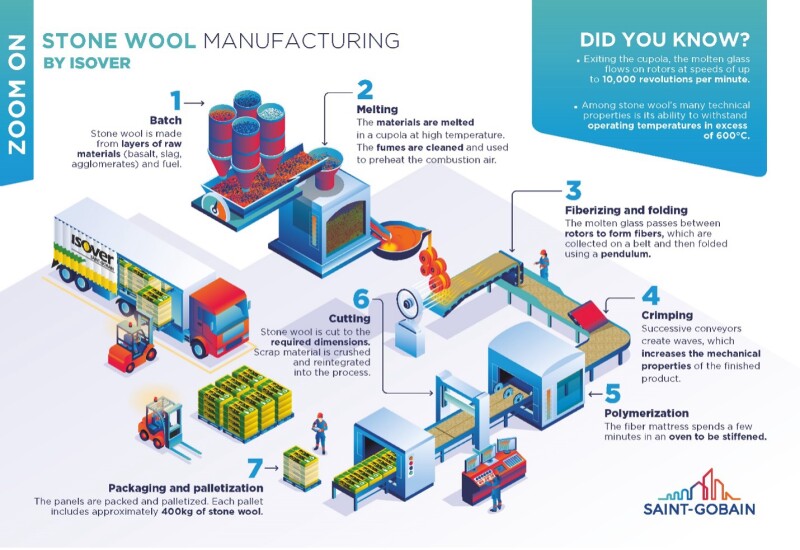

Stone Wool: Also known as mineral wool, rock wool, mineral cotton, or mineral fiber. Stone wool is produced by spinning molten minerals or rocks into fiber strands. Learn More

Properties:

- Thermal Efficiency: High

- Fire Resistance: Excellent

- Acoustic Attenuation: Excellent

- Flexibility: Stone wool is inherently rigid due to the short length of the mineral fibers, making it non-bendable without the use of wired mats.

What Sets Isover's ULTIMATE Stone Wool Apart?

Isover’s ULTIMATE product line, known as 'U Seaprotect' for marine applications, utilizes proprietary, cutting-edge technology to significantly enhance the production process by eliminating 40% of shot and debris before heating. This refinement leads to several key improvements:

- Long Fiber Strands: The technology spins the molten stone into long fiber strands, allowing Isover U Seaprotect to bend around stiffeners without breaking and without the need for wired mats.

- Reduced Thickness and Weight: The removal of shot and debris means the insulation can be thinner yet provide the same fire, thermal, and acoustic properties of thicker traditional stone wool. This translates to lighter products and lighter ships.

- Reduced Resource Usage: The streamlined production process uses less material, which not only lowers procurement costs but also diminishes labor efforts in handling, decreasing overall project costs.

- Transport and Storage Savings: Fewer trucks are needed for transportation, which reduces freight costs and carbon emissions. Additionally, the product's compactness saves valuable storage space. Lighter insulation helps reduce a vessel's overall weight, leading to further savings in fuel and CO2 emissions, corroborated by IMO standards.

- Installation Simplifications: With the material's bendability, installations involve less cutting and trimming, drastically lowering waste generation from 15% to approximately 5%. Isover's stone wool is available in rolls, which are easier to handle and apply compared to traditional slabs. The use of self-adhesive seam tape eliminates the need for additional adhesives, further speeding up the installation process and reducing labor and material costs.

What are the Different Facings Available?

Isover insulation comes with options in thickness, roll or slab form, and various facing types. The facing required depends on the specific application. While G220 and ALU1 are the most popular, many more options are available. Learn about all of them here.

G220 (White Glass Cloth) Facing

The G220 facing is made from white glass cloth, designed for use in marine insulation applications that require a high degree of fire resistance and durability.

Properties:

- Fire Resistance: The glass cloth material is inherently fire-resistant, making it an excellent choice for marine applications where fire safety is critical.

- Thermal Stability: Withstands high temperatures, suitable for areas exposed to significant heat.

- Mechanical Strength: Provides robust protection against mechanical damage, including punctures and tears, essential in harsh operational conditions.

- Aesthetics: The white color of the glass cloth offers a clean and professional look, often desired in visible areas aboard ships.

Applications: - Engine Rooms: Ideal for insulation in high-temperature and high-fire-risk areas.

- Kitchens and Galley Areas: Places aboard ships where fire safety and cleanliness are paramount.

- Visible Sections: Suitable for areas not typically covered, like ceilings and partition walls within passenger ships.

ALU1 (Aluminum) Facing

ALU1 facing consists of an aluminum foil layer, extensively used in marine and offshore insulation solutions where excellent vapor barrier properties are required alongside reflective heat insulation.

Properties:

- Vapor Barrier: Effectively prevents moisture transmission that can degrade insulation and structural integrity.

- Reflective Insulation: Reflects thermal radiation, reducing heating and cooling demands and enhancing energy efficiency aboard vessels.

- Corrosion Resistance: Resistant to corrosion from high humidity and salt spray in marine environments.

- Lightweight: Adds minimal weight, an important factor in marine applications where extra weight can affect fuel efficiency and stability.

Applications: - HVAC Ducts: Protects insulation on HVAC ducts from moisture while improving energy efficiency.

- Pipes: Insulates pipes carrying hot or cold substances, preventing condensation and maintaining temperature levels.

- Exterior Walls: Applied on external walls where moisture barriers and thermal reflectivity improve comfort and reduce energy costs.

- Underdeck Areas: Prevents moisture issues and enhances thermal insulation in exposed underdeck areas.

Standards and Compliance in Marine Insulation

Isover insulation products meet or exceed the following certifications and standards:

- IMO (International Maritime Organization) Standards:

- Part 1: Non-combustibility test (ISO 1182)

- Part 2: Smoke and toxicity test (ISO 5659-2)

- Part 5: Surface flammability test (ISO 5658-2)

- Part 6: Fire propagation test (ISO 5660-1)

These standards ensure that the materials limit the spread of fire, produce minimal smoke and toxins, and resist ignition.

- MED (Marine Equipment Directive) Certification: Confirms compliance with EU marine standards, permitting use on ships in European waters and those registered in EU countries.

- EUCEB Certification: Verifies that mineral wool fibers are bio-soluble, meeting health standards that prevent risks related to inhalation.

- ISO Certifications:

- ISO 9001: Ensures consistent production and quality control.

- ISO 14001: Demonstrates compliance with environmental management requirements for eco-friendly manufacturing.

- CE Marking: Proves the product meets EU safety, health, and environmental protection standards, mandatory in the EEA.

- Lloyd’s Register Approval: Independent verification of compliance with marine and offshore safety standards.

- DNV GL, Bureau Veritas, and ASTM Standards (including ASTM C612 and ASTM E84), along with EN Standards (EN 13501-1 and EN 13162): Ensuring safety, quality, and fire behavior compliance.

Final Thoughts

With numerous options and applications within any given ship, selecting the right insulation for each area can be challenging. The experts at Imtra are ready to help find the ideal solution to fit your specific needs.