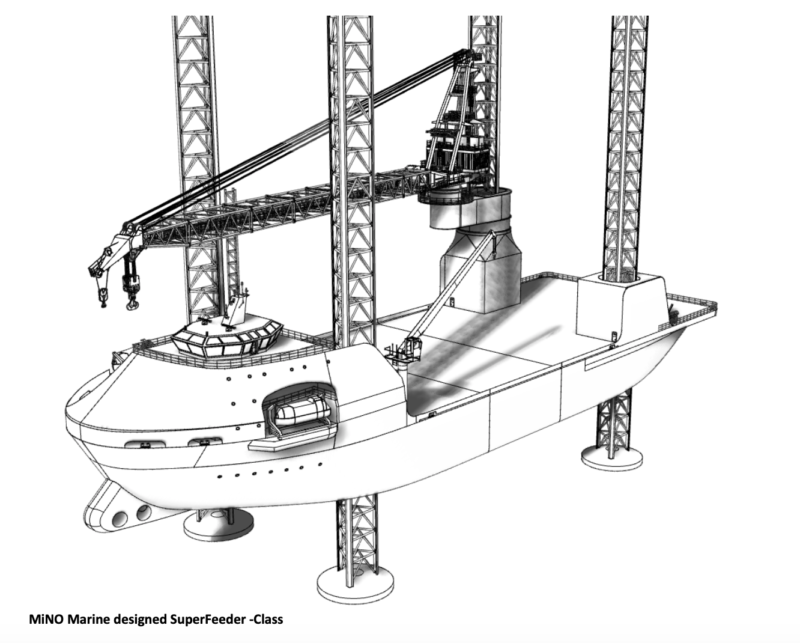

A Louisiana-based offshore services firm and naval architects plan to build a new "superfeeder" class of vessel to provide offshore wind energy developers a Jones Act-compliant system for transporting turbine components from U.S. ports to installation sites.

The 408’x131’x16.4’ “SuperFeeder” will be a fully DP-2 dynamic positioning vessel, propelled by three diesel-electric 2,500-kW Z-drives and two 1,200-kW tunnel bow-thrusters, and capable of 10 knots cruising speed while fully loaded with turbines, foundations and blades, according to 2nd Wind Marine LLC, Galliano, La.

Developed by naval architects MiNO Marine LLC, Jefferson, La., the design is planned for two vessels to be built simultaneously, completed in 2021 to work on more than a dozen wind energy areas leased by developers off the East Coast.

“They will each be capable of transporting one complete set next-generation wind turbine components from U.S. ports to offshore wind farm sites, enabling optimized construction throughput and the most efficient utilization of non-Jones Act compliant wind turbine installation vessels,” according to a statement from the companies.

With early U.S. wind projects dependent on U.S. “feeder barges” carrying components to foreign-flag European wind turbine installation vessels – and the first Jones Act WTIV still a few years away – the time is right for the superfeeder concept, according to Joseph A. Orgeron, business and technology developer for 2nd Wind Marine.

Orgeron worked in 2015-2016 with Deepwater Wind (since acquired by wind developer Ørsted) to bring Gulf of Mexico liftboats north for construction of the Block Island Wind Farm, the first U.S. commercial offshore wind project off Rhode Island. He’s an advocate for the skills and experience that Gulf of Mexico offshore operators can adapt to the nascent East Coast wind industry.

According to the company’s own mission statement, 2nd Wind was created as a “vessel development, erection, and operations firm that intends to manage the design, finance, construction and ultimate operation of a two purpose-built Jones-Act coastwise compliant vessels capable of transporting (or feedering) of large, next-generation offshore wind turbine components from U.S. marshalling ports out to awaiting installation vessels during installation phases and perform specific O&M tasks in the post-installation market.”

The vessels’ power systems will be primarily diesel-electric with medium speed Tier-IV engines. The hulls and superstructures will be configured to accommodate the coming generation of 12-megawatt and larger turbine parts – Orgeron calls the design “future-ready.”

The design has the house offset asymmetrically to the port side, allowing more bow deck space to accommodate larger vertically stacked blade racks. Below decks will accommodate up to 60 persons, counting 20 crew and 40 offshore workers, in single and double berthed, MLC-2006 compliant staterooms.

The cargo deck rated to transport, and jack up with, 4,000 metric tons has a double deck, so changes in grillage can be easily facilitated without concern to tank and void spaces below. Each vessel is intended to carry a complete next-generation turbine set, including tower, generator nacelle and blades.

A unique Liebherr-designed crane, installed around a jacking leg with an offset-pedestal, will allow access to more than 95 percent of the vessel’s cargo deck space. Its lifting capacity will be up lifting each component of next-generation turbines from quayside to the cargo deck. With an extended boom variant, the crane will enable operators to change out blades at sea in the wind turbine arrays.

MiNO Marine developed its designed hull form through extensive engineering analysis using computational fluid dynamics (CFD) methods to yield an efficient hull form suitable for a wide range of offshore operating conditions while also minimizing potential for flow induced drag.

“U.S. shipyards have been engaged and are currently evaluating the design and preparing construction cost and timeline estimates,” the companies said.

“Probably 40, 50 years ago with the rise of the Cajun mariners, my dad was looking in the Gulf of Mexico and saw a great opportunity when the oil and gas companies said how much they were going to spend,” said Orgeron. With the Block Island project, “I saw then there was so much interest in Gulf of Mexico vessels,” he said. ”There was so much more there for Gulf of Mexico operators to look into.”

Join us for a live webinar on Thursday, June 25, where we'll discuss many of these topics and also investigate what the vessel supply chain capabilities currently are, what building a future-ready offshore wind vessel looks like, how creative ideas will ensure timely development and investment, and lastly how characteristics of the northwest Atlantic working environment differ from the European model – and how that will affect vessel design and performance. Click here to register.